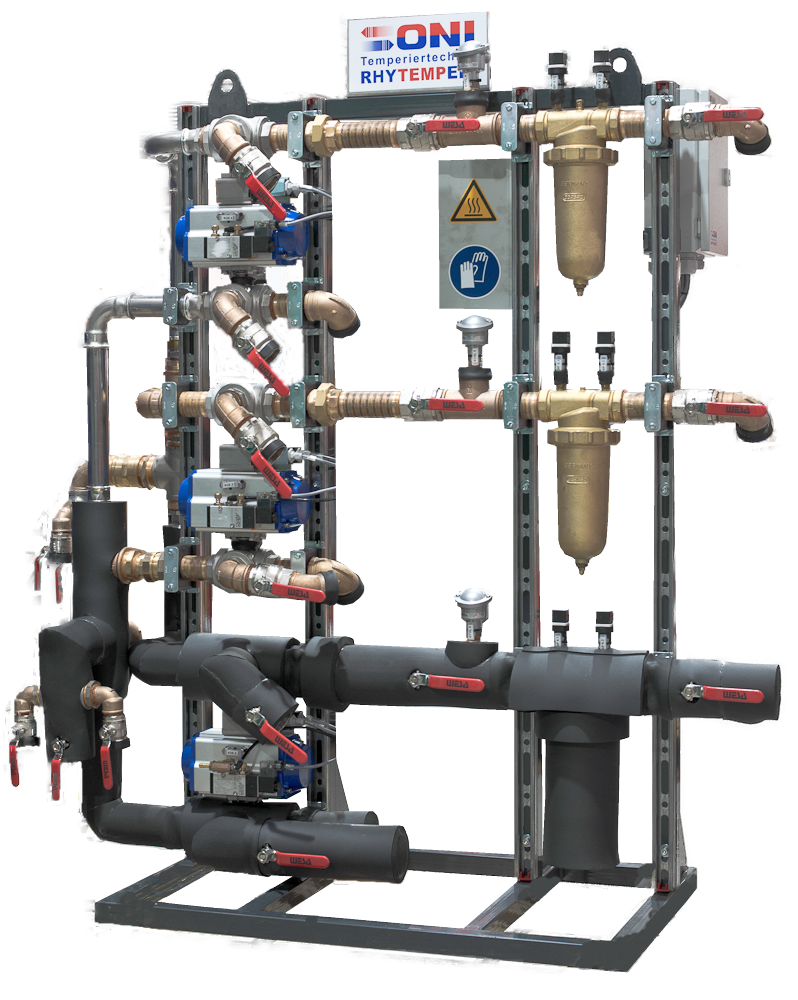

Clean cooling water ensures trouble-free processes!

In closed cooling and temperature control systems, it is crucial to consistently filter out foreign particles from the water circuit. This protects measuring, control, and transport instruments, as well as mold inserts and coupling systems, from potential failures.

To effectively prevent system malfunctions, regular maintenance and cleaning of the filters are mandatory. Maintenance intervals cannot be precisely predetermined, as they depend on the actual level of contamination.

The first filter inspection should take place shortly after commissioning. Based on the amount of debris collected, the timing of the next maintenance or cleaning can be determined. This should occur at least once per quarter, or at the latest when a differential pressure of 0.5 bar is reached.