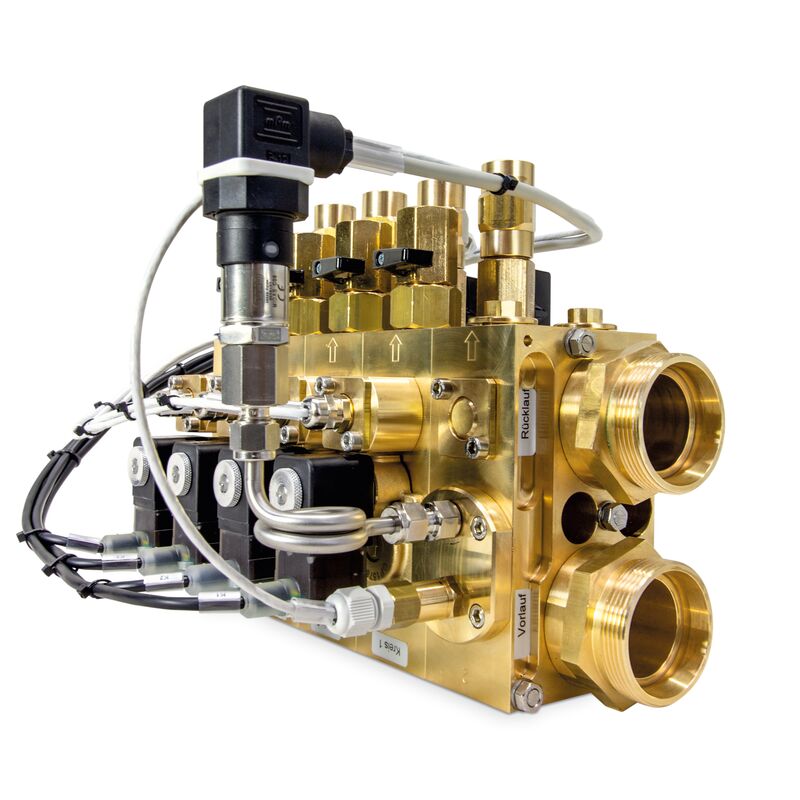

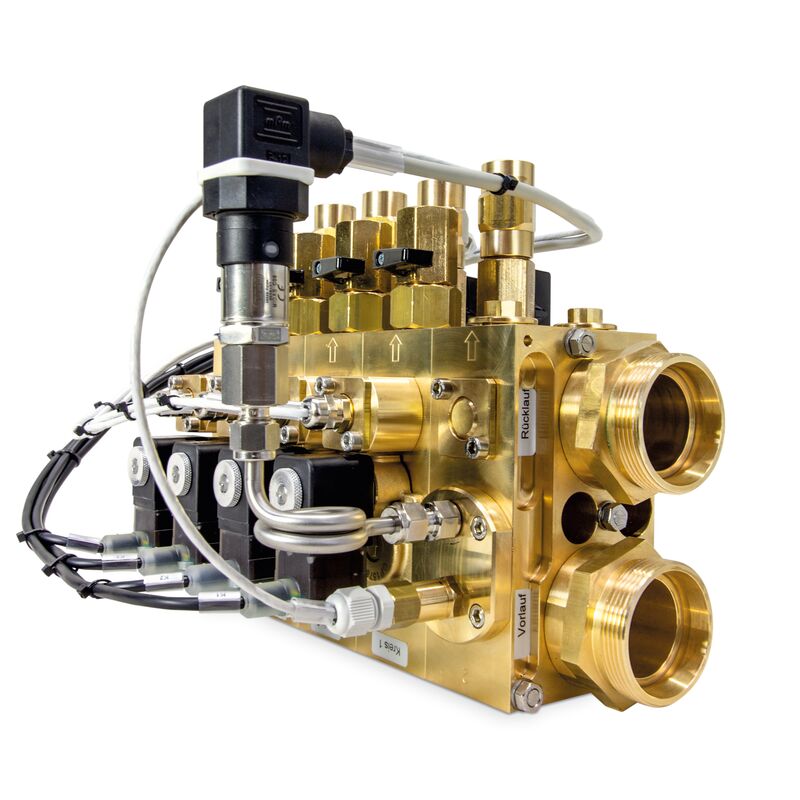

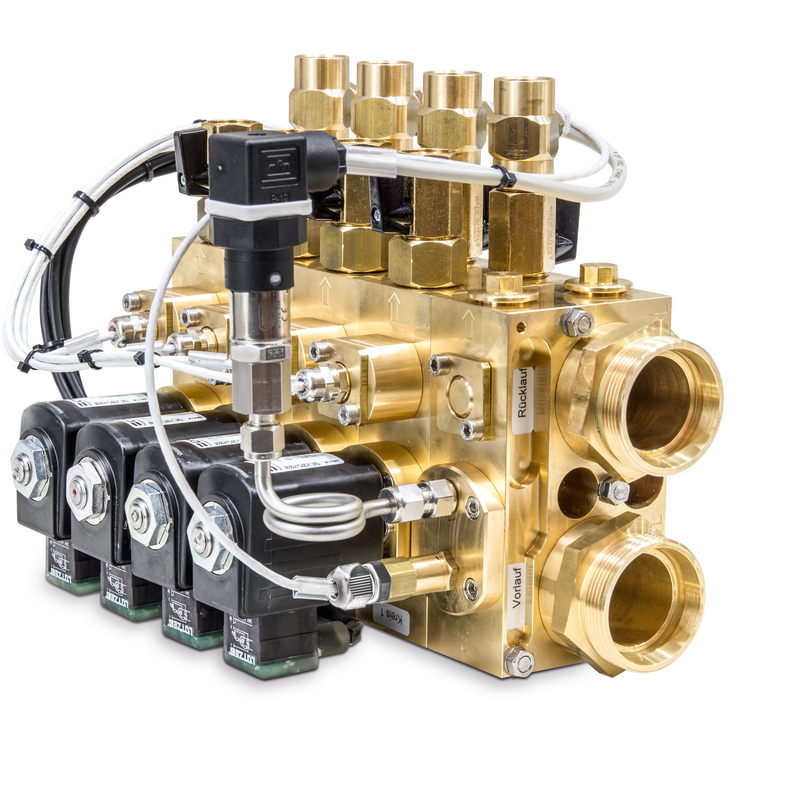

The RHYTEMPER® FlowWatch is a compact water distribution system made from corrosion-resistant materials, designed to monitor the flow and temperature of each individual mold circuit.

FlowWatch

Druckguss

13. - 15. Januar 2026 Euroguss, DE - 90471 Nürnberg, (Halle 4A, Stand 4A-120)

The RHYTEMPER® FlowWatch is a compact water distribution system made from corrosion-resistant materials, designed to monitor the flow and temperature of each individual mold circuit.

The RHYTEMPER® FlowWatch is a compact water distribution system made from corrosion-resistant materials, designed to monitor the flow and temperature of each individual mold circuit.

The Rhytemper® FlexControl is a multi-circuit temperature control system that regulates the heat removal of each individual temperature zone in the injection mold.

The Rhytemper® FlexControl is a multi-circuit temperature control system that regulates the heat removal of each individual temperature zone in the casting mold.

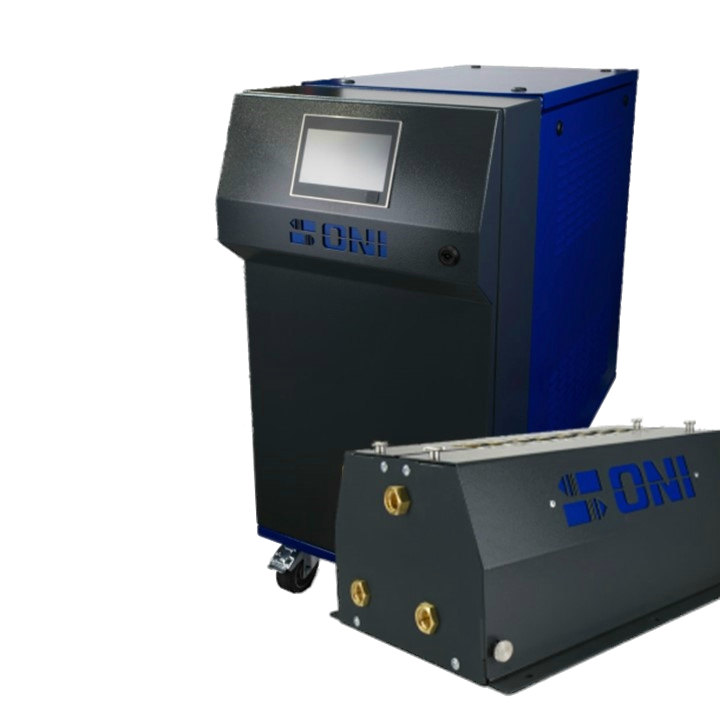

The Rhytemper® HotPulse multi-circuit temperature control system regulates the heat removal of each individual temperature zone in the die-casting mold.

The Rhytemper® HotPulse is a multi-circuit temperature control system that regulates the heat removal of each individual temperature zone in the injection mold.

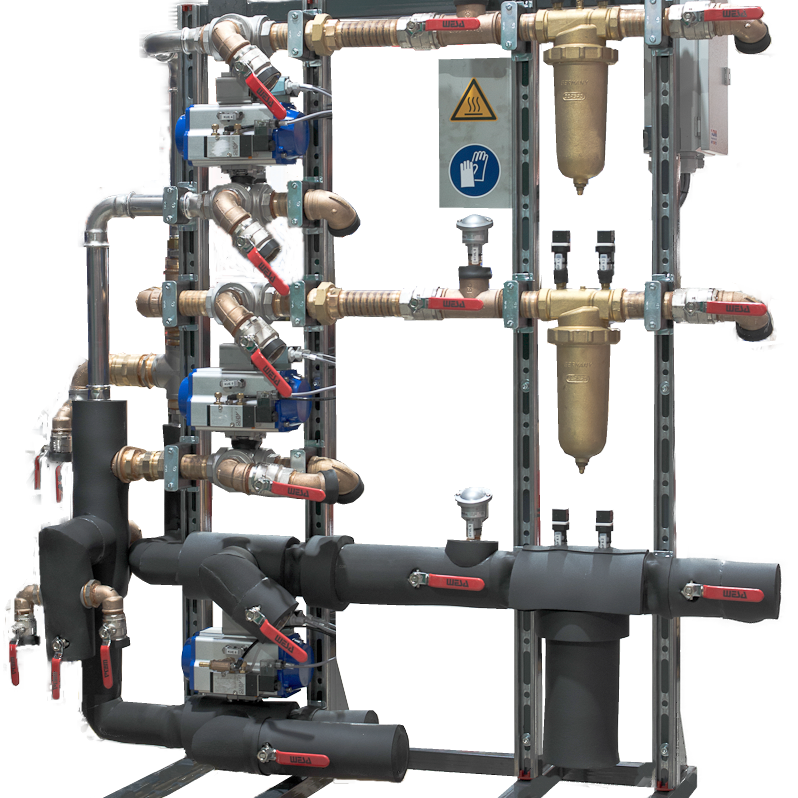

The Rhytemper® FlowControl is a multi-circuit temperature control system designed for individual flow and return temperature regulation of each single circuit.

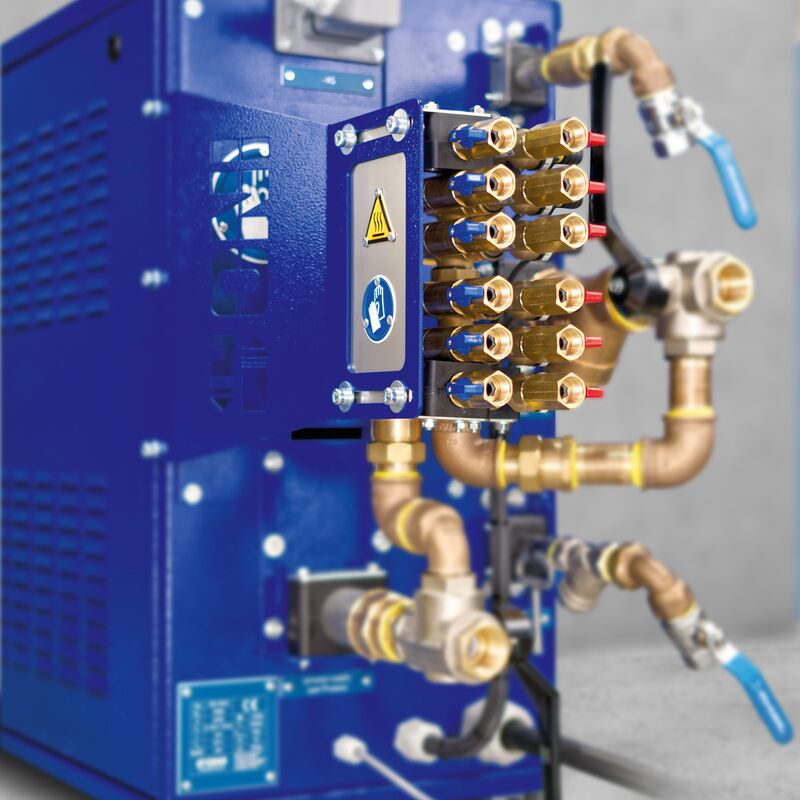

The high-performance temperature control units of the RHY-T90S series are directly cooled and specially designed for multi-circuit temperature control up to 90 °C.

The high-performance temperature control units of the RHY-T95 series are directly cooled and specifically designed for multi-circuit temperature control up to 95 °C.

The high-performance temperature control units of the RHY-HighT140 series are indirectly cooled and specifically designed for multi-circuit temperature control up to 140 °C.

The high-performance temperature control units of the RHY-HighT160 series are indirectly cooled and specifically designed for multi-circuit temperature control up to 160 °C.

The high-pressure cooling units of the CorePulse series are designed for use with pin cores or very small cooling channels in die-casting molds.

Mold drainage systems are used for the effective emptying of cooling channels in die-casting and injection molds before a mold change.

Filter units are designed to sustainably prevent mold contamination and system malfunctions caused by debris or metallic deposits in the cooling water circuit.

Depending on your requirements, we tailor our modules precisely to your needs – perfectly planned, coordinated, and built for your specific process.

Cookiehinweise

Youtube

Schützt vor Cross-Site-Request-Forgery Angriffen.

Speichert die aktuelle PHP-Session.

Text zum Datenschutz