Shorten Cycle Times – Reduce Part Costs

Economic success in plastics processing is achieved only when cycle times are minimized, product quality remains consistently high, and scrap rates are kept low.

| RHY-HighT160 M | RHY-HighT160 L | |

|---|---|---|

| max. Water Supply Temperature | up to 160 °C | up to 160 °C |

| Heating Capacity | 18 / 36 kW | 18 - 108 kW |

| Cooling Capacity Direct / Indirect (ΔT = 70 K) | 220 kW /150 kW (Q = 25l /min) | 220/150 (Standard: Q=25l/min) 400/290 (increased KL: Q=45l/min) |

| Max. Pump Pressure | 9,0 bar | 8,8 bar |

| Max. Pump Flow Rate | 10 m³/h | 35 m³/h |

| Operating Voltage | 400 V AC /3 ~PE/ 50 Hz | Special voltages available on request | 400 V AC /3 ~PE/ 50 Hz | Special voltages available on request |

| Consumer Circuit Connections | 1½ inch | 2 inch |

| Cooling Circuit Connections | ¾ inch | ¾ inch (Standard) 1 inch (increased KL) |

| Length (including connection fittings) | 1072 mm (1279 mm) |

1362 mm (1594 mm) |

| Width | 390 mm | 500 mm |

| Height (lifting eyes) | 910 mm | 1425 mm (1470 mm) |

| Empty Weight | 150 - 250 kg | 400 - 450 kg |

Shorten Cycle Times – Reduce Part Costs

Economic success in plastics processing is achieved only when cycle times are minimized, product quality remains consistently high, and scrap rates are kept low.

Shorten Cycle Times – Reduce Part Costs

Lasting economic success in die casting can only be ensured when cycle times are minimized, product quality remains consistently high, and scrap rates are virtually eliminated.

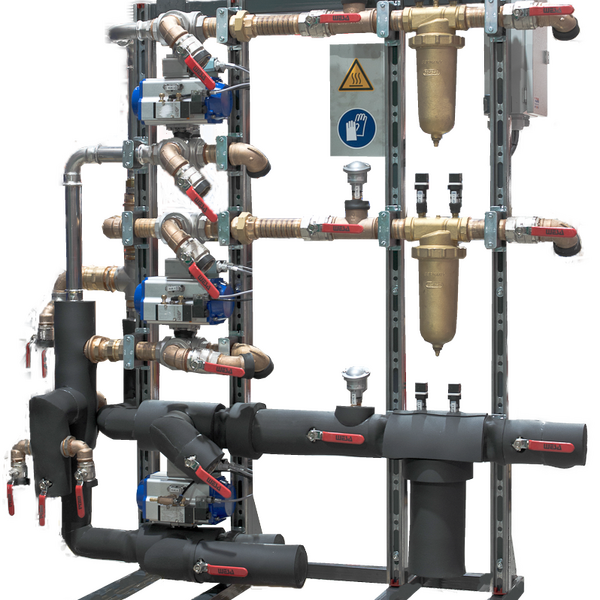

Perfectly Matched Accessories for ONI Temperature Control Systems.

Filter Units

Mold Drainage Systems