Component Quality. Easy Integration into the Die-Casting Cell Through Modular, Compact Design!

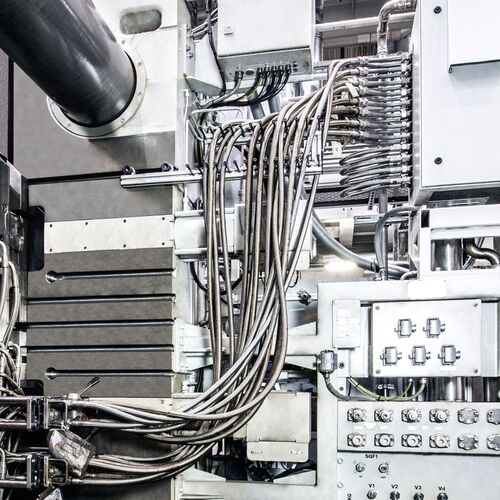

Unlike conventional multi-circuit tempering systems, the Rhytemper® HotPulse can be easily and seamlessly integrated into the die-casting cell. Complex piping from the temperature control unit to the tool becomes a thing of the past. Process-proximate installation ensures precise temperature and flow measurement, with all electronics, sensors, and actuators fully integrated into a compact, foundry-ready enclosure.

The modular design with pre-assembled brass blocks and pre-wired electronics boxes in space-saving protective housings allows installation directly on the mounting plate, close to the process. Each distribution block, with a circuit count tailored to the specific application, is connected via a bus system to other blocks and the main control unit.

Standards for installing distribution blocks directly at the machine manufacturer’s facility have been established with many die-casting machine OEMs. This allows the Rhytemper® HotPulse system to be fully integrated at the factory, piped, and delivered together with the machine as a single, ready-to-use unit.

Economical tempering made easy!

For our hot-water applications, we pay special attention to insulating hoses and piping to minimize heat loss through radiation.

The Rhytemper® HotPulse interface is intuitive and user-friendly, allowing optimal tempering settings to be configured in just a few steps.

The heat removal level for each individual circuit can be adjusted precisely to the part-specific requirements and is visually represented via a color-coded bar for easy operation. Adjustments are made quickly with the “warmer = red” and “cooler = blue” control function.

Each channel is assigned the required operating mode, such as AI-controlled regulation, manual setpoint, continuous operation, or heating.

User-defined parameters are saved in the tool dataset and can be recalled at any time.

Advanced process technicians also have access to a wide range of additional functions for further process optimization, including start-up programs, delayed cooling initiation, leak detection, automatic flow measurement for each cooling channel, and more.